AI and machine learning are revolutionizing freight management by cutting costs, improving efficiency, and solving long-standing logistics challenges.

Here’s a quick snapshot of how AI is transforming the industry:

- Cost Savings: Companies report a 20% drop in logistics expenses and 30% lower maintenance costs.

- Faster Deliveries: AI-driven systems enable 25% faster delivery times and 20% more on-time shipments.

- Smarter Inventory: Reduces excess inventory by 40% and administrative costs by up to 40%.

- Optimized Routes: Real-time route planning cuts empty truck miles by 50% and saves millions on fuel.

- Demand Forecast Accuracy: AI improves forecasting accuracy by up to 98%, reducing supply chain errors by 50%.

- Market Growth: The AI supply chain market is projected to reach $41.23 billion by 2030.

AI tools like predictive maintenance, dynamic pricing, and automated carrier selection are helping companies stay competitive. However, challenges like data quality, system integration, and workforce training remain key hurdles.

To implement AI successfully, businesses must focus on strong data systems, seamless integration, and employee upskilling.

AI is not just the future of freight management – it’s happening now.

Demand Forecasting with AI

AI-driven demand forecasting is reshaping freight management by improving accuracy and reducing inefficiencies.

McKinsey Digital reports that using AI for forecasting can cut supply chain errors by 30% to 50% and decrease lost sales from out-of-stock situations by as much as 65%

Data-Driven Demand Prediction

Modern AI tools combine multiple data sources to deliver highly accurate demand forecasts. Here are some key data types and their roles:

| Data Type | Role in Forecasting |

|---|---|

| Historical Sales | Highlights recurring patterns and trends |

| Market Conditions | Reflects current economic factors |

| Seasonal Trends | Predicts cyclical changes in demand |

| Competitor Activity | Considers market competition and dynamics |

| Real-time Data | Uses live inputs like website and social media |

For example, TIP Trailer Services, which manages over 70,000 transport units across Europe, achieved impressive results with AI:

- 98% accuracy for 2-week forecasts

- 95% accuracy for 6-week projections

- An 11% potential revenue boost through improved one-way rentals

“AI-enhanced forecasting reduces errors in supply chain networks by 30 to 50%.” – McKinsey Digital

These detailed predictions pave the way for smarter inventory decisions.

Smart Inventory Management

AI has revolutionized inventory management by minimizing both overstocking and stockouts.

This leads to lower transportation and warehousing costs (5–10%) and significantly reduced administrative expenses (25–40%)

Take the National Healthcare Service Blood and Transplant (NHSBT) as an example.

They used machine learning to forecast demand for 40 blood products across 15 distribution hubs. The results? A 54% reduction in expired platelets and complete elimination of costly emergency transport.

In retail, Walmart applied AI algorithms to monitor product stock levels with 95% accuracy, which contributed to a 15% gain in employee productivity.

To maximize the benefits of AI in demand forecasting, companies should focus on:

- Building strong data management systems

- Ensuring smooth integration with current infrastructure

- Training models with high-quality historical data

- Encouraging collaboration between AI specialists and operational teams

Route Planning and Cost Reduction

AI-powered route planning is changing how freight is managed by analyzing data in real time to create more efficient and cost-effective routes.

Live Route Updates

AI-driven route optimization systems adapt on the fly, using live data to adjust routes based on:

| Factor | Impact on Route Planning |

|---|---|

| Traffic Conditions | Avoids congestion by rerouting vehicles |

| Weather Events | Steers clear of hazardous conditions |

| Road Closures | Adjusts for construction or accidents |

| Delivery Windows | Ensures deliveries meet scheduled times |

| Vehicle Capacity | Balances load distribution |

| Driver Hours | Keeps operations compliant with regulations |

Real-world applications of AI-driven routing have shown significant cost savings and efficiency gains for logistics companies. For example, large-scale implementations have led to:

- A reduction in fuel consumption by millions of gallons annually

- Operational cost savings in the hundreds of millions of dollars

- Increased efficiency across tens of thousands of delivery routes

Results: AI Route Planning

Real-time route adjustments offer clear benefits:

- Convoy‘s Automated Reloads Program. This program cut empty-mile emissions by 45% by bundling shipments. It now handles 100% automated load matching in key U.S. markets.

- Dorman‘s Warehouse Operations By adopting AI-driven fulfillment systems, Dorman achieved:

- 30% less forklift labor

- $4.2 million saved in three years

- 50% reduction in worker travel time

The demand for route optimization tools is growing fast. The market is expected to hit $8.659 billion by 2029. This growth highlights the technology’s ability to:

- Cut unnecessary mileage

- Lower fuel costs

- Reduce vehicle maintenance

- Boost driver productivity

- Limit overtime expenses

“Dynamic routing can transform transportation by using real-time data and advanced algorithms.”

According to industry research, 86% of third-party logistics providers (3PLs) rank advanced routing algorithms among their top three tech priorities.

Meanwhile, 88% of carriers focus on AI for optimizing fleets. These numbers highlight the increasing reliance on AI to streamline freight operations.

Freight Rates and Carrier Selection

AI is now simplifying decisions around freight rates and carrier choices, building on advancements in routing technology.

Market Rate Analysis

AI-powered rate management tools dig into market data to fine-tune pricing. They help spot:

- Overpriced rates

- Unnecessary surcharges

- Fake or inflated invoices

These tools use the same principles that improved routing to bring more efficiency to rate management.

Carrier Performance Tracking

AI doesn’t just stop at pricing – it also evaluates carriers by looking at historical data, current demand, coverage, communication quality, risk factors, and how well they stick to contracts.

This leads to better decision-making and improved performance scoring.

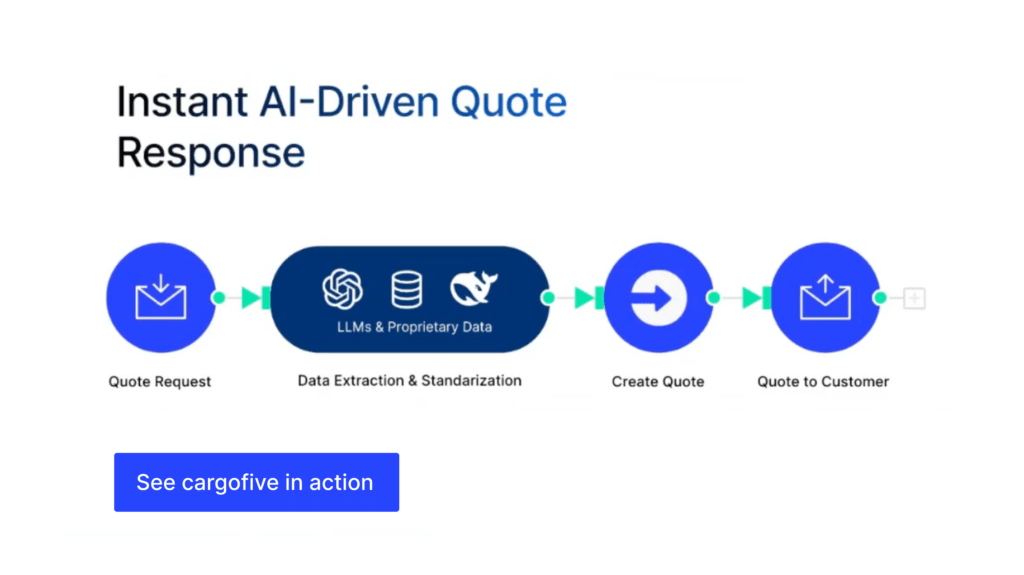

Cargofive has developed a platform that simplifies freight operations, saving forwarders 90% of their time, reducing costs by 25%, and processing millions of rates and contracts.

Our automated system quickly analyzes rates from various sources, integrates with over 25 shipping lines, and offers real-time visibility into ocean, local, and inland charges

Equipment Maintenance and Fleet Control

AI and IoT are reshaping how freight operations handle equipment maintenance and fleet management. By using real-time data, these technologies help avoid breakdowns and streamline operations.

Smart Maintenance Systems

Freight operators now rely on AI-driven predictive maintenance tools to spot potential issues before they escalate into failures.

These systems monitor key factors like engine temperature, vibration levels, and component wear to schedule maintenance ahead of time.

A great example of this is Long Beach Fleet Services’ use of Pitstop‘s AI-based maintenance system. In December 2022, the system flagged dozens of hybrid vehicles at risk of battery failure during the holiday season.

This early warning allowed the team to act quickly, avoiding costly downtime when employees returned to work.

Integrating AI into maintenance systems has delivered measurable benefits:

| Benefit | Impact |

|---|---|

| Downtime Reduction | 30% fewer unplanned maintenance stops |

| Cost Savings | 20% lower overall maintenance expenses |

| Fleet Efficiency | 15% boost due to better scheduling |

| Vehicle Lifespan | 20–25% longer equipment life expectancy\ |

But AI’s impact doesn’t stop at maintenance – it also brings major improvements to fleet management.

Fleet Management Results

Companies using AI-powered fleet management systems are seeing impressive outcomes. For instance, a Fortune 500 Automotive Retail and Supply Chain company used real-time sensor data to achieve:

- A 25% cut in delivery times

- A 20% boost in on-time deliveries

- A 35% drop in manual labor costs

- A 12% increase in overall productivity

The system paid for itself within a year and delivered a 250% return on investment within two years.

AI Implementation Hurdles and Trends

Common AI Setup Challenges

AI is reshaping freight management, but it’s not without its challenges. While over 65% of companies have adopted AI in at least one area of their operations, many struggle to expand its use across the board.

One major hurdle is ensuring high-quality data and seamless system integration.

Legacy systems and outdated infrastructure often create bottlenecks, requiring businesses to invest in data cleaning, standardization, and phased upgrades to modernize their technology.

Another issue is a lack of expertise. According to a Skillsoft report, 66% of executives rate their teams’ AI skills as medium to low.

“Implementing AI without strategic planning and execution can set you back rather than propel you forward.”

Addressing these challenges is essential, especially as new technologies continue to transform freight management.

Future Tech and Changes

AI is driving significant changes in freight management. The AI in Logistics Market is expected to hit $549 billion by 2033, growing at an annual rate of 46.7% from 2024 to 2033.

Despite current challenges, emerging technologies are helping to tackle these obstacles:

- Advanced Analytics: The global Generative AI market, valued at $44 billion in 2023, is projected to grow at a 47.5% annual rate through 2030.

- Computer Vision: Currently worth $17.7 billion, this market is expected to grow by 19.6% annually through 2026. Maersk’s UK facility leveraged Berkshire Grey’s AI-driven system to triple sorting speeds and boost batch picking efficiency by 33%.

- Automation: In the near future, automation will continue to reshape the logistics industry, with many companies planning to adopt automated warehouse operations, leading to notable increases in efficiency and cost savings

PwC estimates that AI could add $15.7 trillion to the global economy by 2030.

This surge is fueled by improvements in predictive analytics, route optimization, automated documentation, real-time supply chain tracking, and smarter maintenance scheduling.

To stay competitive, companies need to invest in modern infrastructure, workforce training programs, and strong data management systems, all while prioritizing security and compliance.

Next Steps and Summary

AI Benefits Overview

Recent studies reveal that companies using AI in freight management see major improvements: 74% in customer service, 69% in IT operations, and 66% in planning.

For instance, a Fortune 500 automotive company reported impressive results after adopting AI – delivery times cut by 25%, on-time deliveries increased by 20%, transportation costs reduced by 22%, and a 250% return on investment within just two years.

These numbers highlight how AI can reshape areas like route planning, demand forecasting, and inventory management.

If you’re looking to achieve similar results, here’s a practical guide to help you integrate AI into your operations.

Getting Started with AI

To make the most of AI’s capabilities in logistics and freight management, follow these actionable steps:

- Assessment and Planning: Evaluate current freight management processes, warehouse efficiency, route optimization opportunities, and areas where customer experience can improve.

- Data Foundation: Collect historical sales data from ERP systems, incorporate real-time GPS and traffic information, use IoT sensors for live updates, and ensure data consistency across platforms.

- Strategic Implementation:AI is redefining freight forwarding by enabling smarter logistics, predictive analytics, and automation. Forward-thinking companies leveraging AI will optimize efficiency, reduce costs, and stay ahead in an increasingly competitive industry.

- Technology Integration: Use predictive analytics to forecast demand, adopt automated route planning, implement AI-powered robotics in warehouses, and establish real-time tracking systems.

- Training and Support: Offer hands-on training for new tools, enhance the technical expertise of your team, set clear operational guidelines, and provide ongoing support for a smooth transition.

With the AI supply chain market expected to hit $41.23 billion by 2030, there’s no better time to start.

Begin with small, focused projects, scale up as you see results, and always prioritize data quality and security throughout the process.

AUTHOR